Our NIR analyzers :

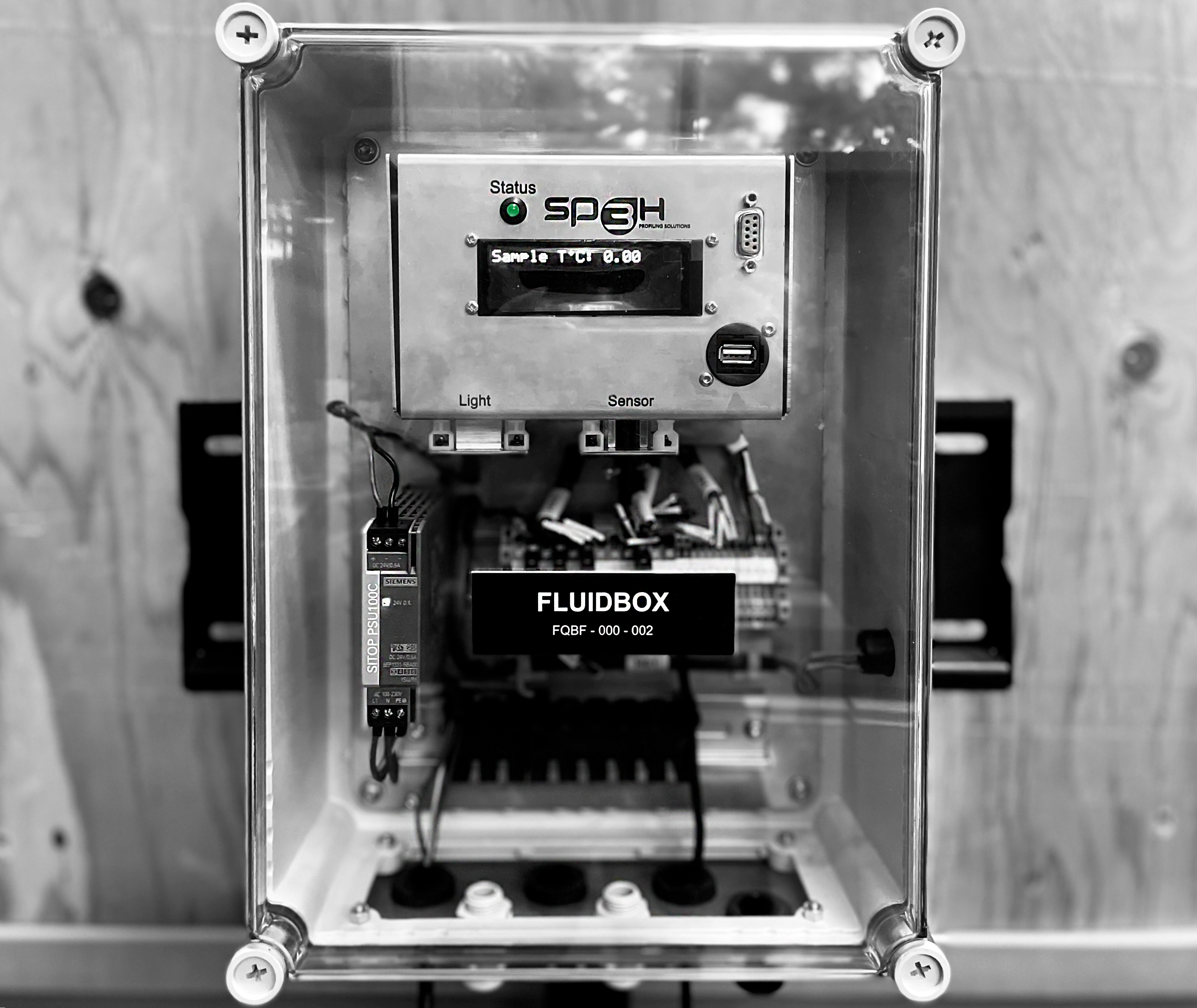

The FLUIDBOX

SP3H, THE WORLD’S LEADING SUPPLIER OF INTELLIGENT OPTICAL SENSORS

Based on its previous experience in the oil, agronomy and waste recycling industries, the SP3H team was the first in the world to develop a miniaturized solution for analyzing fluid molecular structures using near infrared spectrometers, compatible with harsh environments (temperature, vibration) allowing on-board or on-line and real-time monitoring of fuel and fluid quality.

FLUIDBOX MICRO

FLUIDBOX SPECTRO

With or without Optical Fibers

FLUIDBOX EX

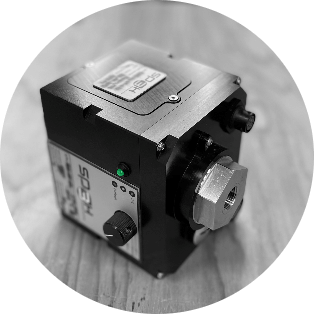

FLUIDBOX MICRO

The FluidBOX Micro is a smart optical scanner based on near-infrared technology (NIR) enabling the identification of the molecular structure of any organic fluid. The sensor is a mini-version of the on-line analyzers used by the oil industry since the early 1990s to monitor on-line and in real time the quality of the fuel during the blending operation.

APPLICATION

Embedded solution for predicting the qualities of fuels, biofuels and synthetic fuels (gasoline, diesel, kerosene, etc.). Fuel Quality Certificate (CO2; Pollutant Emissions) for Low Emission Zones (LEZ)

MARKET

The FluidBox micro is designed for the markets of road, non-road, marine, rail, aerospace, farm machinery and power generation (Genset – diesel group).

DETAILS

The extreme miniaturization of the housing allows installation on the chassis or in the engine compartment of the vehicle. Operating conditions cover a temperature range of -20 to 85°C and fuel flows up to 500 L/H under 20 bars. The FluidBOX is equipped with a CAN 2.0 connector.

FLUIDBOX SPECTRO

Compact and robust, offering unparalleled stability and precision in size, our FluidBox Spectro systems are pre-calibrated to a temperature range from -20°C to 85°C for the non-fibred solution, without compromising on performance. The fiber version allows analysis to be delocalized by using optical fibers to measure products under extended process conditions (temperature; pressure).

APPLICATION

The applications are multiple thanks to a wide selection of spectral ranges and a choice of stainless-steel measuring cell or Aluminum thus allowing integration into process. Our FluidBox Spectro can integrate signal processing as well as specific mathematical/statistical models to predict various properties of the analyzed fluid (WATER content, % Alcohol, % Sugar, % reagents, …).

MARKET

The FluidBox Spectro is destined for the process industry market (Chemistry, Agri-food, petrochemicals, etc.)

DETAILS

Our technology is based on 30 years of experience in the use and development of NIR spectrometer instruments for on-line processes. Near Infrared Spectroscopy (NIR) is a non-invasive, non-destructive and real-time method widely used in most process industries (production control and process optimization) for more than 4 decades for continuous analysis of fluid properties. The sensors are equipped with an RS485 connection.

FLUIDBOX SPECTRO NON ATEX

The FluidBox Spectro, equipped with fibre optics, is an advanced solution dedicated to non-ATEX zones or pre-selection approaches. Designed for demanding industrial environments, it combines robustness and precision.

APPLICATION

This technology is ideal for applications requiring fast, accurate and flexible fluid analysis under standard industrial conditions. With more than 2.5 years of proven service, the FluidBox Spectro FQBF has established itself as a reliable, high-performance solution for on-line spectroscopic analysis in environments not classified as ATEX.

MARKET

The FluidBox Spectro is destined for the process industry market (Chemistry, Agri-food, petrochemicals, etc.)

DETAILS

Resistant casing : made from high-strength polyamide or polyester, IP65-rated and offering excellent chemical resistance, particularly to ketones.

Calibrated temperature range : 0°C to +50°C, ensuring reliable performance even in variable conditions.

NIR technology : Select from 3 NIR spectral ranges (1350-1650 nm, 1650-1950 nm, 1750-2150 nm) as required.

Integrated PT100 temperature sensor : For accurate measurements and reliable temperature correction.

FLUIDBOX EX

FluidBox Ex: the world’s first compact on-line NIR analyzer with the ATEX zone 1 specification, low CAPEX and OPEX enabling digital transformation

APPLICATION

The FluidBox Ex incorporates the same specificities and advantages as the FluidBox Micro and FluidBox Spectro solutions, with ATEX/IECEx type certification, allowing installation near production units (Zone 1)

MARKET

Refining and petrochemical industries, more generally Oil & Gas

DETAILS

The FluidBox Ex is intended for process industries requiring ATEX/IECEx certification. The case has a 4/20 mA analog output and a digital output (RTU/ModBUS). The length of the optical fibers and the choice of the sampling cell are made according to the customer’s needs.